Leadership Genesee members become advocates for Genesee County business

Press Release:

On Wednesday, February 26, members of the Leadership Genesee Class of 2025 met at Liberty Pumps in Bergen to begin their journey into discovering all kinds of things in relation to Genesee County’s Business & Economics. As one member shared, it was an AMAZING day, I learned so much about my city and my county!

At Liberty Pumps, the group participated in an activity designed to identify how much of their expendable income is spent in Genesee County. Much of our shopping today is done online for time and convenience. However, the group learned that by supporting local businesses, it ensures the vitality of the local economy and job creation which is good for everyone. What is spent local, stays local as 65 cents of every dollar spent remains in our community and even when shopping at a local big box store, the county retail sales tax stays here.

Mark Masse LG ’02, President & CEO of the Genesee County Economic Development Center (GCEDC), explained their purpose is to facilitate local economic growth and development, which fosters investment and job creation for the benefit of our residents and children. The organization has a board of directors, ensuring the vision is accomplished. He shared how the organization helps market and fund projects to bring them to Genesee County, ultimately helping grow the tax base for our residents.

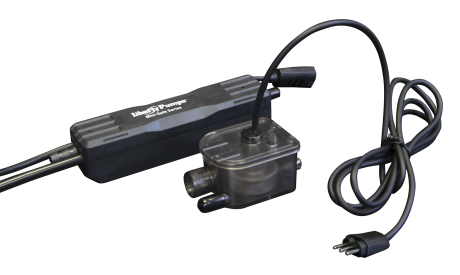

Robyn Brookhart LG ’02, Chief Executive Officer and Dennis Burke LG ’01, Chief Financial Officer at Liberty Pumps gave the class perspective of how important their organization’s corporate culture is and how they work to maintain it. It is collaborative, communicative, and engaging where all members are respected. Their business has grown from 50 employees 20 years ago to over 330 today. They are intentional in words and actions which was evident as the class toured the manufacturing plant.

Class members visited 17 local businesses to get an all-around view of how important local business leaders work for their families, their customers and for the Genesee County economy.

The day ended at Eli Fish where the class heard Matt Gray LG ’11 talk about his business/ leadership journey and plans for future business development. The sentiment felt by everyone was that the entire day opened them up to reflect on how and where they spend their money and exactly why it matters.

February’s session was hosted by Liberty Pumps, Inc. and Eli Fish Brewing Co. Meals were sponsored by Lawley and Gavin M. Townsend, Lic. RE Salesperson at HUNT ERA Batavia.

Leadership Genesee is a program of Cornell Cooperative Extension of Genesee County, an employer and educator recognized for valuing AA/EEO, Protected Veterans, and Individuals with Disabilities and provides equal program and employment opportunities. For more information, visit LG’s website at http://genesee.cce.cornell.edu/leadership-genesee; “like” LG on Facebook at www.facebook.com/leadershipgenesee; or contact Program Director Peggy Marone at 585-343-3040, ext. 118 or mem77@cornell.edu.

Submitted photos.