A new partnership with the Batavia Career and Technical Education Center (BOCES) and Cornell University is paving the way for students interested in a career in precision machining.

The unique program, which is the only such partnership in the nation, allows students to study realistic particle accelerator hardware designs and fabricate hardware based on those designs, said Maggie Fitzgibbon, head of public relations at Genesee Valley Educational Partnership.

“Within the next several years, the Cornell-BNL Energy Recovery Linacs Test Accelerator at the Cornell Laboratory for Accelerator-based Sciences and Education (CLASSE) will develop into a powerhouse of accelerator physics and technology and will be one of the most advanced in the world,” said Lora K. Gruber-Hine, director of Education and Outreach Programs at the Cornell laboratory.

“The building of ERL will require the cultivation of local talent and a highly trained workforce. When this prototype ERL is complete and expanded upon, it will be a critical resource to New York State, the nation and the world, propelling science, biomedical advancement and economic development.”

Tim Gleba, precision machining instructor, was instrumental in development of the new partnership. After watching a video on the Cornell High Energy Synchrotron Source Facebook page explaining how machinists work to create parts for the particle accelerator at Cornell, he was intrigued and thought this could possibly be a project for his students.

He pitched his idea to Cornell and a meeting last summer resulted in development of a project plan for this school year.

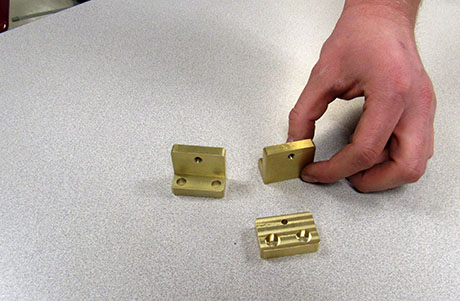

Batavia CTE’s precision machining students are now creating 150 parts for Cornell’s particle accelerator. These include adjustment plates and brackets, as well as a short dipole spacer bar. These parts are used to align magnets within a tolerance of .004 inches, Gleba said.

“This partnership is a wonderful opportunity for these high school students,” Gleba said. “They are able to work with Cornell’s engineers, physicists and machinists.”

Development of the partnership adds a whole inventive aspect to the precision machining curriculum and provides students with relevant work experience, Gleba added.

“Our machine shop and Cornell’s are virtually the same,” he said. “Cornell has the identical machines as us and also uses the same software as what we have in our Precision Machine Shop here in Batavia.”

Students recently toured the Wilson Synchrotron Laboratory at Cornell to kick off the new partnership, according to Fitzgibbon.

Gruber-Hine said they want to showcase the partnership and the new technologies being developed.

She and Gleba both commented on the shortage of trained employees in the precision-machining industry.

“Our lab has been sensitized to the shortage, and as we are growing, the need for skilled labor becomes more evident," Gruber-Hine said. “We realize the need to cultivate a relationship with institutions that train skilled professionals to fill this middle skills gap. When Tim watched our video, he wanted to form a relationship with our laboratory that would allow his students to work on meaningful machining products and contribute to the work being done here.”

“Within the next five years, it is anticipated 50 percent of the precision machining workforce will be retiring, leaving an incredible gap,” Gleba said.

The Precision Machining class at Batavia BOCES had been discontinued for several years, after longtime instructor David O’Geen retired, Fitzgibbon said. But when several high school students expressed an interest in the field, Gleba was hired three years ago in an effort to resurrect the program.

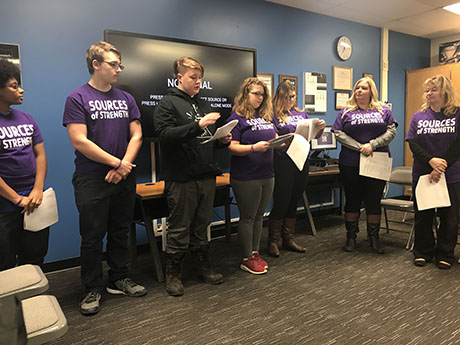

Four of those students are Ayden Odachowski, James Roggow, Benjamin LaBombard and Evan Bartz.

Bartz said he wanted to get into machining because he knew the field was exploding.

Bartz and Roggow worked together to create a process to machine both sides of spacer bars.

Jon Sanfratello, executive principal of the Batavia campus, which includes the Batavia CTE Center, commented on how this partnership provides students with the chance to learn advanced manufacturing skills. The Precision Machining Program is currently affiliated with the National Aeronautics and Space Administration’s HUNCH program. Along with manufacturing hardware for Space X-10, students learn how to inspect and analyze the parts to meet the expert standards set forth by NASA.

“We pride ourselves in offering innovative programs that give our students real-world applicable learning opportunities,” Sanfratello said. “In this new partnership with CLASSE, our students will study cutting-edge designs, learn modern manufacturing methods so they are equipped to succeed in the 21st century workforce.”

“The goal of this partnership is to inspire the next generation of machinists and trades professionals by providing educational opportunities for students to work in concert with engineers and technical directors,” Gruber-Hine added.

Top photo: Tim Gleba, right, instructor in the Precision Machining Program at Batavia Career and Technical Education Center, and student James Roggow show some of the parts the class is making for the particle accelerator at Cornell University.

Above, four of the students in the Precision Machining Program at Batavia Career and Technical Education Center are, from left, Ayden Odachowski, James Roggow, Benjaming LaBombard and Evan Bartz. The Center is engaged in a partnership with Cornell University’s lab to make parts for the college’s particle accelerator. This is the first such partnership in the nation with high school students.

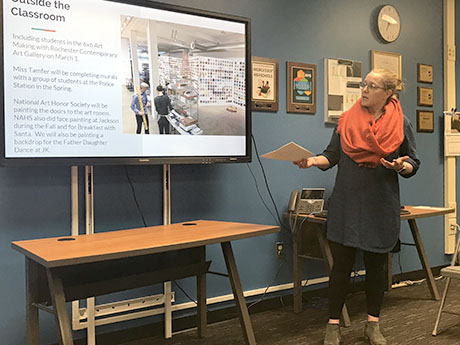

Tim Gleba, instructor in the Precision Machining program at the Batavia Career and Technical Education Center, holds one of parts made by high school students in his class in a one-of-a-kind partnership with Cornell University. Gleba was hired three years to train precision machinists, which are in dire need throughout the area. Gleba said Cornell and industry in the region will be looking to hire 100 precision machinists within the next five years.

This is an example of the parts machined by students at the Batavia Career and Technical Education Center. The program was revived three years ago to train precision machinists for the industry.