The timeline has been pushed back, but expectations are still high for the eventual success of 1366 Technologies, the Bedford, Mass.-based solar wafer maker that anticipates eventually creating 1,000 new jobs in Genesee County.

Even as the process moves along slowly, 1366 continues to go forward.

Last week, the company announced a new record in solar power efficiency for a wafer in their product category; in August it unveiled a new beveled edge on its wafer, which helps retain wafer strength while keeping the wafer very thin.

These breakthroughs will help further reduce the cost of the energy produced by solar panels that use 1366's wafers.

The stated goal of 1366 is to help make the production of electricity from solar cheaper than electricity produced by coal.

That might have seemed like a moonshot-ambition when plans to locate 1366's manufacturing plant in the Town of Alabama were first announced two years ago, but the cost of solar energy has dropped by two-thirds in recent years and there are parts of the world now where solar arrays are producing electricity at a cost below that of coal.

In the rapidly evolving technology field, it might seem like delays in getting a new plant open would cause the business owners to worry about losing precious time, but that isn't the case, according to a spokeswoman for 1366.

"I’m sure you’ve noted this, but our path to commercial success has been methodical from day one," Laureen Sanderson said. "It’s one of the reasons why we’re now in a position to scale in a big way. It’s incredibly important to us that we’re careful stewards of all resources sent our way – private and public – and we think we’ve done a good job of balancing the demands to get to market quickly while taking what we see as essential steps to remove all risk – like getting a customer contract in place before a factory is even built."

The cost reductions achieved by the solar industry so far are largely incremental and the result of increasing scale, not big improvements in the technology. The silicon wafers used in solar panels today are made the same way solar wafers have been made for 40 years. The 1366 process is radically different.

Because the company is built around patented, proprietary technology and processes, officials believe they will come to market with a disruptive and competitive advantage whenever they ramp up to full-scale production.

"Direct Wafer technology is a singular achievement," Sanderson said. "We’re the first and only company to solve this manufacturing challenge. There are many great solar innovations out there but they’re in labs. Science projects. It takes years to move from the lab to the factory floor; most ideas never do. What we’ve achieved isn’t easy and the industry knows that."

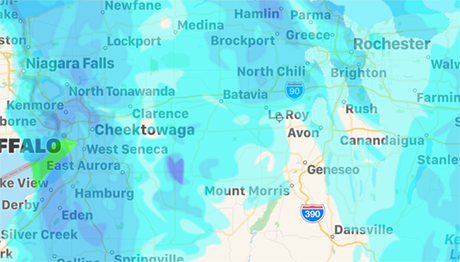

What exactly is delaying groundbreaking at the new technology park in Alabama, WNY STAMP, isn't clear.

When we've asked Steve Hyde -- CEO of Genesee County Economic Development Center and the first advocate for a technology park in Genesee County more than a decade ago -- about the delays, he says everybody is continuing to diligently work on the process; there is ongoing progress, and he quotes one of his favorite phrases, "Economic development is a marathon. It isn't a sprint."

A year ago, officials expected to break ground in the spring. In September, Hyde said there would be a groundbreaking in the fall. Now, the earliest estimate is this coming spring.

Reached this morning, Hyde said infrastructure and construction bidding will start after the first of the year. Water service and the main entrance road will be bid out first.

"2017 will be a busy year for construction," Hyde said.

Frank van Mierlo, CEO of 1366, told E&E News earlier this year that he expects to be up and running at STAMP by the end of 2017. Van Mierlo reportedly told E&E that "permitting and red tape" have slowed progress.

"We're moving," he said. "It's certainly not moving as rapidly as one might hope."

"It's going to be a stretch," he added. "The end of the year rather than the beginning. We definitely want to be in construction next year."

The reason everyone remains so upbeat about the prospects of 1366 is it seems like the company has charted a solid business model built on breakthrough technology.

This isn't PepsiCo trying to enter an already crowded Greek yogurt sector with a barely differentiated product and hoping marketing and supply chain alone could win. This is a company entering an emerging industry with growing demand and a process that will substantially reduce the cost of production.

"Nobody is close. We can produce the wafer at 30 cents a wafer," van Mierlo told E&E News. "Even at today's prices, you are still very profitable. At today's prices, nobody else is profitable. That is the point.

"There's no false modesty here," he added. "Our technology is truly revolutionary when it comes to reducing costs."

In his best-selling business book, "Zero to One," venture capitalist Peter Thiel says new businesses should be built around innovations that are a 10-times improvement over anything currently in the market. 1366 seems to be hitting that mark.

"The Direct Wafer process is a dramatic improvement over the way wafers are manufactured today and it’s specific to us," Sanderson said. "(We achieve a) 50-percent reduction in cost and two-thirds energy reduction over conventional (production) methods. Better yet is the product – which costs less and uses less (energy) to make, doesn’t require any tradeoffs in performance."

That's why the recent efficiency tests were so important.

Efficiency is the measure of how much sunlight that hits a solar wafer is converted into electricity. The 1366 wafer was tested in conjunction with new technology from a partner company, Hanwha Q CELLS Co. Ltd., of Seoul, South Korea.

While there is other solar technology that has achieved higher efficiency, that isn't the norm in the industry.

"In a head-to-head comparison with standard high-performance multicrystalline (HPM) wafers, we exceeded the average performance of that HPM reference group," Sanderson said. "And there are more gains to be had through new wafer features that are possible because we’re able to work at the melt level. There’s no other company in the world able to do that."

In the startup world, the common advice, and the practice often most attractive to potential investors is a company that aims at a specific market segment, an achievable target that promises growth.

For 1366, their approach is to make only wafers (compared to Solar City, opening in Buffalo, that makes not just the wafer, but the entire solar panel and even handles installation) and sell them to companies on an international market that will make panels for industrial solar installations.

That's a very specific market, and 1366 already has customers lined up, most notably, Hanwha, their partner in the recent efficiency tests. The company has also secured an investment from silicon supplier Wacker Chemie.

Silicon, of course, is the key ingredient in making solar wafers. It's a derivative of sand, but unlike the process used to make silicon wafers for four decades, which involves shaving down silicon ingots into the appropriate shape and thickness, 1366 wafers are poured from molten silicon, like glass is made, using techniques developed at MIT.

This is why the wafers that will be made in Genesee County will cost less and produce less waste.

A key reason 1366 picked STAMP as its eventual manufacturing home is the availability of low-cost hydropower, itself an environmentally friendly, renewable energy source. That will also make it easier for 1366 to keep production costs down.

The proximity to Buffalo, however, has invited comparisons between 1366 and Solar City, which is opening at Riverbend and has been an ongoing source of speculation and controversy, but 1366 and Solar City are really very different companies.

Solar City, as noted, is a vertically integrated manufacturer and distributor -- so much so that company Chairman Elon Musk has merged Solar City with Tesla, his company that makes electric cars. Musk wants to control the entire energy supply chain for his vehicles, from converting to solar energy to powering the batteries that Telsa makes, too.

A big part of Solar City's business model has long been residential solar installations, a market that has been seemingly dependent on state and federal tax subsidies, subsidies that have come under criticism and may not last under the Trump Administration.

While Trump campaigned on a promise to save coal jobs, every cabinet appointment he's made so far, notably Rex Tillerson, CEO of Exxon for secretary of state, and Rick Perry, for the Department of Energy, are hardly friendly to coal. They're interest lies closer to natural gas, currently coal's primary competitor for electricity generation, but that also wouldn't seem to bode well for backers of solar power.

Sanderson said 1366 isn't worried.

"Solar is a global industry and it’s growing rapidly," Sanderson said. "That’s not changing. Our technology will further support this growth as we continue the trend of costs coming down. We help to make solar even more accessible and we want to support this global growth with U.S. manufacturing and U.S. jobs."

There's still plenty of R&D work to do on solar, Sanderson noted, and 1366 received early-stage R&D funding from the Department of Energy.

"It’s important to keep in mind that while we’re a solar company, we’re also a manufacturer," Sanderson said. "We’re looking forward to working with the next administration to create U.S. manufacturing jobs."

In this case, of course, U.S. manufacturing jobs should translate into Genesee County manufacturing jobs. Time will tell.